Umshini wokugaya i-Gantry uyisisetshenziswa esivamile sokucubungula insimbi esinezici eziyingqayizivele nezisebenzayo zesakhiwo.Okulandelayo, ngizokwethula izici zesakhiwo somshini wokugaya i-gantry ngokuningiliziwe.

1. Isakhiwo sihlanganisa ikakhulukazi izingxenye ezilandelayo:

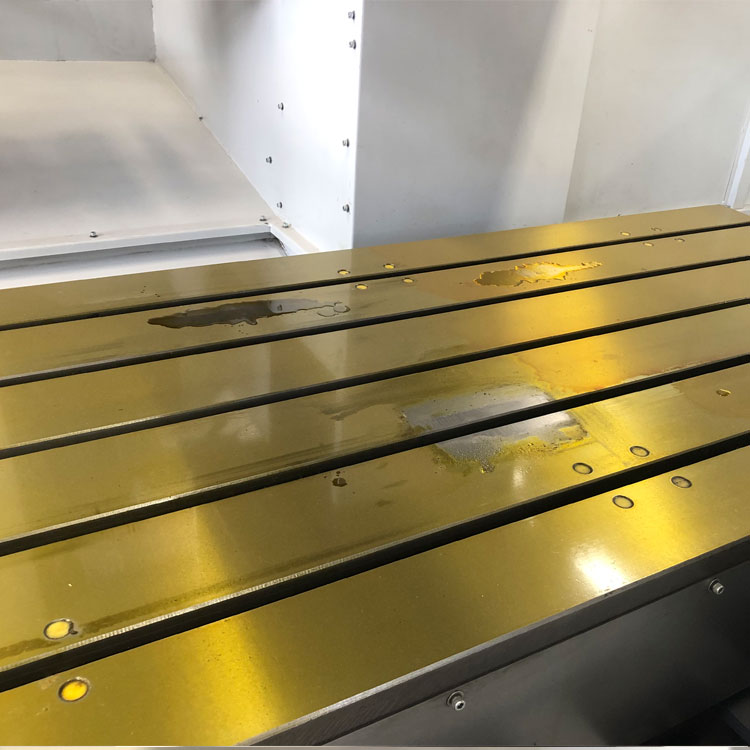

Umbhede: Umbhede uyingxenye eyinhloko yomshini wokugaya i-gantry, ngokuvamile eyenziwe nge-cast iron, enokuqina okwanele nokuzinza.Umbhede ufakwe ibhentshi lokubeka nokulungisa izinto zokusebenza okufanele zicutshungulwe.

I-Beam: I-beam itholakala ngaphezu kombhede, ngesimo se-gantry, futhi izinhlangothi ezimbili ze-beam zisekelwa amakholomu.Umsebenzi oyinhloko we-beam ukuhlinzeka ngendawo yokucubungula, ukusekela nokulungisa ibhentshi lokusebenzela eligudlukayo.

Okuthunyelwe: Okuthunyelwe kuhlala nhlangothi zombili zombhede futhi kusekela imishayo.Ikholomu ngokuvamile yenziwe ngensimbi yensimbi, enamandla anele kanye nokuqina ukuze kuqinisekiswe ukuzinza nokunemba kwawo wonke umshini wokugaya i-gantry.

Ibhentshi Lokusebenzela: Ibhentshi lokusebenzela liyipulatifomu esetshenziselwa ukubeka nokulungisa i-workpiece ezocutshungulwa, ngokuvamile embhedeni.Ibhentshi lokusebenzela lingakwazi ukuya emuva naphambili futhi kwesokunxele nakwesokudla ukuze kube lula ukuma nokucubungula ama-workpieces.

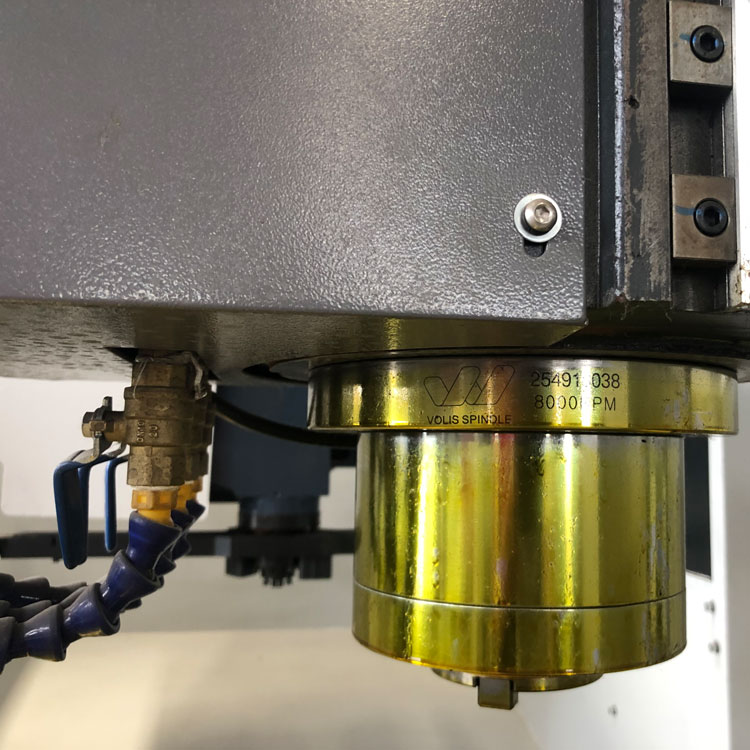

I-spindle: I-spindle iyingxenye eyinhloko yomshini wokugaya i-gantry, esetshenziselwa ukufaka nokushayela ithuluzi.I-spindle ivamise ukushayelwa yinjini ukuze kuzuzwe ukuzungezisa ngesivinini esiphezulu, kanti i-workpiece isikwa yithuluzi.

Uhlelo lokulawula: Umshini wokugaya i-gantry ufakwe uhlelo oluthuthukisiwe lokulawula izinombolo ukuze ulawule futhi ulungise inqubo yomshini.Umsebenzisi angasetha amapharamitha wokucubungula ngohlelo lokulawula, njengejubane lokusika, isivinini sokuphakelayo, njll., ukuze afeze ukucubungula okunembile.

2. Izici zesakhiwo:

Umshini wokugaya i-gantry uphinde ufakwe uhlelo lokulawula ama-axis amaningi, okwenza kube nemisebenzi ehlukahlukene yokucubungula.Ngesistimu yokulawula, opharetha angakwazi ukulungisa ngokuguquguqukayo imingcele yokucubungula ukuze afinyelele ukucutshungulwa kobumo obuhlukene, osayizi nokujula.Lolu hlelo lokulawula ama-axis amaningi aluthuthukisi nje kuphela ukunemba nokusebenza kahle kwemishini, kodwa futhi lwenza umshini wokugaya i-gantry ube nezinhlelo eziningi ezibanzi.

Umshini wokugaya i-gantry nawo unamandla okusika ngesivinini esiphezulu kanye nekhono lokucofa okuphezulu.Ifakwe i-spindle enesivinini esikhulu namathuluzi okusika okusika okusheshayo nokunemba kwezinto zensimbi.Ngesikhathi esifanayo, umshini wokugaya i-gantry uphinde usebenzise izinzwa ezithuthukisiwe nezinhlelo zokulawula, ezingakwazi ukuqapha nokulungisa inqubo yokucubungula ngesikhathi sangempela ukuze kuqinisekiswe ukunemba kanye nekhwalithi yokucubungula.

Umshini wokugaya i-gantry nawo unezinga eliqinile lokuzenzakalela.Ingahlonyiswa ngezinto ezisizayo ezifana nesistimu yokuguqula ithuluzi elizenzakalelayo kanye nesistimu yokulayisha nokulayisha okuzenzakalelayo ukuze ibone ukuzenzela nokuqhubeka kwenqubo yokucubungula.Lokhu akugcini nje ngokuthuthukisa ukusebenza kahle kokukhiqiza, kodwa futhi kunciphisa izindleko zabasebenzi kanye nokuqina komsebenzi.

Izici zesakhiwo somshini wokugaya i-gantry zihlanganisa isakhiwo se-gantry, isistimu yokulawula i-axis eminingi, ukusika ngesivinini esiphezulu kanye nekhono eliphezulu lokunemba kwemishini, kanye ne-automation eqinile.Lezi zici zenza umshini wokugaya i-gantry ube yimishini ebalulekile futhi ebalulekile emkhakheni wezimboni wesimanje, ohlinzeka ngokusekelwa okuqinile kokukhiqizwa kwayo yonke imikhakha yokuphila.

Isikhathi sokuthumela: Jul-22-2023