Izintambo ezijwayelekile ziyizinsimbi ezivundlile ezingacubungula izinhlobo ezahlukene zezinto zokusebenza njengama-shaft, amadiski, izindandatho, njll.

umsebenzi wesakhiwo

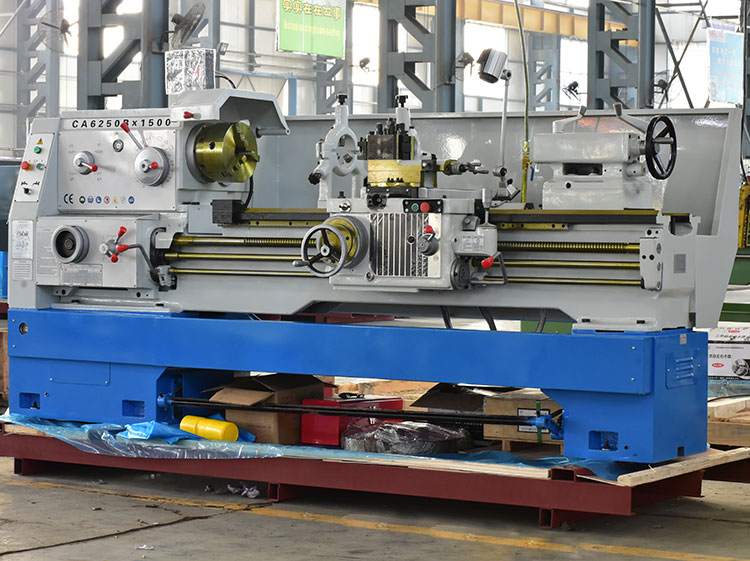

Izingxenye eziyinhloko ze-lathe evamile yilezi: i-headstock, ibhokisi lokuphakelayo, ibhokisi lamaslayidi, indawo yokuphumula yamathuluzi, i-tailstock, isikulufu esibushelelezi, isikulufu sokuhola nombhede.

I-Headstock: Eyaziwa nangokuthi i-headstock, umsebenzi wayo oyinhloko ukudlulisa ukunyakaza okujikelezayo kusuka ku-motor enkulu ngokusebenzisa uchungechunge lwezindlela zokushintsha isivinini ukuze i-shaft enkulu ikwazi ukuthola isivinini esidingekayo sokuya phambili nokuhlehla, futhi ngesikhathi esifanayo i-headstock ihlukanisa ingxenye yamandla Dlula ukunyakaza ebhokisini lokuphakelayo.I-Headstock Medium spindle iyingxenye ebalulekile ye-lathe.Ukushelela kwe-spindle egijima ku-bearing kuthinta ngqo ikhwalithi yokucubungula ye-workpiece.Uma ukunemba kokujikeleza kwe-spindle kwehlisiwe, inani lokusetshenziswa kwethuluzi lomshini lizoncishiswa.

Ibhokisi lokuphakelayo: Futhi elaziwa njengebhokisi lamathuluzi, ibhokisi lokuphakelayo lifakwe indlela yokushintsha isivinini yokunyakaza kokuphakelayo.Lungisa indlela yokushintsha isivinini ukuze uthole inani elidingekayo lokuphakelayo noma ukuphakama, futhi udlulisele ukunyakaza emmese ngesikulufu esibushelelezi noma ngesikulufu somthofu.i-rack yokusika.

Isikulufu somthofu nesikulufu esibushelelezi: sisetshenziselwa ukuxhuma ibhokisi lokuphakelayo nebhokisi lokushelela, futhi kudluliselwe ukunyakaza namandla ebhokisi lokuphakelayo ebhokisini elislayidayo, ukuze islayidi

phila phezulu

Ikhreyithi ithola ukunyakaza komugqa we-longitudinal.Isikulufu sokuhola sisetshenziswa ngokukhethekile ekuphenduleni imicu ehlukahlukene.Lapho uphendulela ezinye izindawo ze-workpiece, kusetshenziswa isikulufu esibushelelezi kuphela, futhi isikulufu sokuhola asisetshenziswa.

Ibhokisi lesilayidi: Yibhokisi lokulawula ukunyakaza kwe-lathe.Ifakwe umshini oguqula ukunyakaza kwebha yokukhanya kanye nesikulufu sokuhola sibe ukunyakaza komugqa kwendawo yokuphumula yamathuluzi.Ukunyakaza kokuphakelayo kwe-longitudinal kanye nokunyakaza kokuphakelayo okuphambene nendawo yokuphumula yamathuluzi kubonakala ngokudluliswa kwebha yokukhanya.Futhi ukunyakaza okusheshayo, ngokusebenzisa isikulufu ukushayela isibambi sethuluzi ukwenza ukunyakaza komugqa we-longitudinal, ukuze uphendule intambo.

Isiphathi samathuluzi: Isibambi samathuluzi sakhiwe izendlalelo ezimbalwa zabaphathi bamathuluzi.Umsebenzi wayo ukubophela ithuluzi nokwenza ithuluzi lihambe ngobude, libheke eceleni noma ngokugobile.

I-Tailstock: Faka isikhungo esingemuva ukuze uthole ukwesekwa kokuma, futhi ungafaka amathuluzi okucubungula imigodi njengama-drill nama-reamer ukuze kucutshungulwe imbobo.

Umbhede: Izingxenye eziyinhloko ze-lathe zifakwe embhedeni, ukuze zigcine isikhundla esinembile esihlobene phakathi nomsebenzi.

isithasiselo

1. I-chuck yemihlathi emithathu (yezingcezu zokusebenza eziyisilinda), i-chuck yemihlathi emine (yezinto zokusebenza ezingajwayelekile)

2. Isikhungo esibukhoma (sokulungisa izinto zokusebenza)

3. Uhlaka olumaphakathi (ucezu lokusebenza oluzinzile)

4. Ngesiphatho sommese

isici esiyinhloko

1. I-torque enkulu emazingeni aphansi kanye nokukhishwa okuzinzile

2. Ukusebenza okuphezulu kwe-vector control

3. Impendulo ye-torque eguquguqukayo esheshayo kanye nokunemba kokuqiniswa kwesivinini esikhulu

4. Yehlisa ijubane futhi ume ngokushesha

5. Ikhono eliqinile lokulwa nokugxambukela

Izinqubo zokusebenza

1. Ukuhlola ngaphambi kokushayela

1.1 Faka amafutha afanele ngokweshadi lomshini wokugcoba.

1.2 Hlola zonke izinsiza zikagesi, isibambo, izingxenye zokudlulisa, ukuvikela kanye nemishini yokukhawulela ukuthi kuphelele, kuthembekile futhi kuyavumelana nezimo.

1.3 Igiya ngalinye kufanele libe ku-zero, futhi ukuqina kwebhande kufanele kuhlangabezane nezidingo.

1.4 Akuvunyelwe ukugcina izinto zensimbi ngqo embhedeni, ukuze zingalimazi umbhede.

1.5 I-workpiece ezocutshungulwa ayinalo udaka nesihlabathi, ivimbela udaka nesihlabathi ukuthi zingaweli kuphalethi futhi ziguge nomzila wesitimela.

1.6 Ngaphambi kokuba i-workpiece iboshwe, ukuhlolwa kwemoto okungenalutho kufanele kwenziwe.Ngemuva kokuqinisekisa ukuthi konke kujwayelekile, i-workpiece ingalayishwa.

2. Izinqubo zokusebenza

2.1 Ngemuva kokufakwa kwe-workpiece, qala iphampu kawoyela wokugcoba kuqala ukuze wenze umfutho kawoyela uhlangabezane nezidingo zethuluzi lomshini ngaphambi kokuqala.

2.2 Lapho ulungisa i-rack gear rack, lapho ulungisa isondo elilengayo, ukunikezwa kwamandla kufanele kunqanyulwe.Ngemuva kokulungiswa, wonke ama-bolts kufanele aqiniswe, i-wrench kufanele isuswe ngesikhathi, futhi i-workpiece kufanele inqanyulwe ukuze kusetshenziswe isilingo.

2.3 Ngemuva kokulayisha nokukhipha i-workpiece, isikrufu se-chuck nezingxenye ezintantayo ze-workpiece kufanele zisuswe ngokushesha.

2.4 I-tailstock, isibambo se-crank, njll. yethuluzi lomshini kufanele ilungiswe endaweni efanele ngokuya ngezidingo zokucubungula, futhi izoqiniswa noma iboshwe.

2.5 Izinto zokusebenza, amathuluzi nezinto ezilungiswayo kumele zifakwe ngokuvikelekile.Ithuluzi lamandla antantayo kufanele linwebe ingxenye yokuhola endaweni yokusebenza ngaphambi kokuqala ithuluzi lomshini.

2.6 Uma usebenzisa indawo yokuphumula emaphakathi noma indawo yokuphumula yamathuluzi, isikhungo kufanele silungiswe kahle, futhi kube nokugcotshwa okuhle nokusekela izindawo zokuthintana.

2.7 Lapho ucubungula izinto ezinde, ingxenye ephumayo ngemuva kwe-shaft eyinhloko akufanele ibe yinde kakhulu.

2.8 Lapho uphakela ummese, ummese kufanele usondele emsebenzini kancane ukuze ugweme ukungqubuzana;ijubane lenqola kufanele lifane.Lapho ushintsha ithuluzi, ithuluzi kanye ne-workpiece kufanele igcine ibanga elifanele.

2.9 Ithuluzi lokusika kufanele liboshwe, futhi ubude besandiso bethuluzi lokujika ngokuvamile abudluli izikhathi ezingu-2.5 ubukhulu bethuluzi.

2.1.0 Uma kwenziwa izingxenye ezingagxilile, kufanele kube nesisindo esifanele sokulinganisa isikhungo samandla adonsela phansi e-chuck, futhi isivinini semoto kufanele sifaneleke.

2.1.1.Kumele kube nezinyathelo zokuvikela izingcezu zokusebenza ezidlula i-fuselage.

2.1.2 Ukulungiswa kwesethingi yethuluzi kumele kuhambe kancane.Uma ithiphu lethuluzi liku-40-60 mm kude nengxenye yokucubungula yesiqeshana sokusebenza, kufanele kusetshenziswe okuphakelayo okwenziwa ngesandla noma okusebenzayo, futhi okuphakelayo okusheshayo akuvunyelwe ukubandakanya ithuluzi ngokuqondile.

2.1.3 Lapho upholisha i-workpiece ngefayela, isibambi sethuluzi kufanele sibuyiselwe endaweni ephephile, futhi opharetha kufanele abhekane ne-chuck, isandla sokudla sibe ngaphambili nesandla sobunxele ngemuva.Kukhona ukhiye ongaphezulu, futhi i-workpiece enembobo yesikwele ayivunyelwe ukucutshungulwa ngefayela.

2.1.4 Lapho epholisha indilinga yangaphandle ye-workpiece ngendwangu ye-emery, osebenzisa i-emery kufanele abambe iziphetho ezimbili zendwangu ye-emery ngezandla zombili ukuze azipholishe ngokuvumelana nokuma okuchazwe esihlokweni esandulele.Akuvunyelwe ukusebenzisa iminwe yakho ukuze ubambe indwangu e-brasive ukupholisha imbobo yangaphakathi.

2.1.5 Ngesikhathi sokuphakelwa kommese okuzenzakalelayo, isibambi sommese esincane kufanele silungiswe ukuze sishaywe ngesisekelo ukuvimbela isisekelo ukuthi singathinti i-chuck.

2.1.6 Lapho usika izingcezu zokusebenza ezinkulu nezisindayo noma izinto zokwakha, imali eyanele yomshini kufanele igcinwe.

3. Umsebenzi wokupaka

3.1 Nquma amandla bese ukhipha ucezu lokusebenza.

3.2 Izibambo zengxenye ngayinye ziwiswa phansi ukuze zibe ziro, futhi amathuluzi ayabalwa futhi ahlanzwe.

3.3 Hlola isimo sedivayisi ngayinye yokuvikela.

4. Izinyathelo zokuqapha ngesikhathi sokusebenza

4.1 Akuvunyelwe ngokuphelele ukuthi abangasebenzi basebenzise umshini.

4.2 Akuvunyelwe ngokuphelele ukuthinta ithuluzi, ingxenye ejikelezayo yethuluzi lomshini noma i-workpiece ejikelezayo ngesikhathi sokusebenza.

4.3 Akuvunyelwe ukusebenzisa isitobhi esiphuthumayo.Esimeni esiphuthumayo, ngemva kokusebenzisa le nkinobho ukuyeka, kufanele ihlolwe futhi ngokuvumelana nemithethonqubo ngaphambi kokuqala ithuluzi lomshini.

4.4 Akuvunyelwe ukunyathela phezu komzila wesitimela, induku yesikulufu, induku epholishiwe, njll. ye-lathe.Ngaphandle kwemithethonqubo, akuvunyelwe ukusebenzisa isibambo ngezinyawo esikhundleni sezandla.

4.5 Ezingxenyeni ezinamabhamuza, izimbobo ezishwabene noma okhiye odongeni lwangaphakathi, ama-scrapers angama-triangular awavunyelwe ukusika izimbobo zangaphakathi.

4.6 Umoya ocindezelweyo noma umfutho we-liquid we-pneumatic hydraulic chuck yangemuva kufanele ufinyelele inani elishiwo ngaphambi kokuthi usetshenziswe.

4.7 Lapho uphendula ama-workpieces amancane, lapho ubude obuphumayo bezinhlangothi ezimbili zangaphambili zekhanda lombhede bungaphezu kuka-4 ububanzi, isikhungo kufanele sisetshenziswe ngokuvumelana nemithetho yenqubo.Ukuphumula kwesikhungo noma ukwesekwa kokuphumula kwesithende.Onogada nezimpawu eziyisixwayiso kufanele kwengezwe lapho kuphumela ngaphandle kwekhanda lombhede.

4.8 Uma usika izinsimbi eziphukayo noma ukusika okuchaphazeka kalula (okuhlanganisa nokugaya), ama-baffles okuvikela kufanele kwengezwe, futhi opharetha kufanele bagqoke izibuko zokuzivikela.

Imibandela Yokusebenzisa

Ukusetshenziswa okuvamile kwama-lathes ajwayelekile kufanele kuhlangabezane nezimo ezilandelayo: ukushintshashintsha kwamandla kagesi endaweni yethuluzi lomshini kuncane, izinga lokushisa elizungezile lingaphansi kuka-30 degrees Celsius, kanti umswakama ohlobene ungaphansi kuka-80%.

1. Izidingo zemvelo zendawo yethuluzi lomshini

Indawo yethuluzi lomshini kufanele ibe kude nomthombo wokudlidliza, ukukhanya kwelanga okuqondile nemisebe eshisayo kufanele kugwenywe, futhi umthelela womswakamo nokugeleza komoya kufanele kugwenywe.Uma kunomthombo wokudlidliza eduze kwethuluzi lomshini, ama-grooves anti-vibration kufanele asethwe eduze kwethuluzi lomshini.Uma kungenjalo, kuzothinta ngokuqondile ukunemba komshini nokuzinza kwethuluzi lomshini, okuzodala ukuthintana okungalungile kwezingxenye ze-elekthronikhi, ukwehluleka, futhi kuthinte ukuthembeka kwethuluzi lomshini.

2. Izidingo zamandla

Ngokuvamile, ama-lathes ajwayelekile afakwa ku-workshop yomshini, hhayi kuphela izinga lokushisa elizungezile elishintsha kakhulu, izimo zokusebenzisa zimbi, kodwa futhi kunezinhlobo eziningi zemishini ye-electromechanical, okuholela ekuguquguqukeni okukhulu kugridi yamandla.Ngakho-ke, indawo lapho kufakwa khona ama-lathes ajwayelekile idinga ukulawulwa okuqinile kwamandla kagesi.Ukushintshashintsha kwamandla kagesi kumele kube phakathi kwebanga elivumelekile futhi kuhlale kuzinzile.Uma kungenjalo, ukusebenza okuvamile kohlelo lwe-CNC kuzothinteka.

3. Izimo lokushisa

Izinga lokushisa elizungezile lama-lathes ajwayelekile lingaphansi kuka-30 degrees Celsius, futhi izinga lokushisa elihlobene lingaphansi kwama-80%.Ngokuvamile, kune-fan yokukhipha umoya noma isiphephetha-moya esipholile ngaphakathi kwebhokisi lokulawula ugesi le-CNC ukuze kugcinwe izinga lokushisa elisebenzayo lezingxenye ze-elekthronikhi, ikakhulukazi iyunithi yokucubungula emaphakathi, okungaguquki noma umehluko wezinga lokushisa ushintsha kancane kakhulu.Ukushisa okudlulele kanye nomswakama kuzonciphisa impilo yezingxenye zesistimu yokulawula futhi kuholele ekuhlulekeni okwandisiwe.Ukwanda kwezinga lokushisa nomswakama, kanye nokwanda kothuli kuzodala ukubopha ebhodini lesifunda elihlanganisiwe futhi kubangele ukujikeleza okufushane.

4. Sebenzisa ithuluzi lomshini njengoba kushiwo kumanuwali

Uma usebenzisa ithuluzi lomshini, umsebenzisi akavunyelwe ukushintsha amapharamitha asethwe umkhiqizi ohlelweni lokulawula ngokuthanda kwakhe.Ukulungiselelwa kwalawa mapharamitha kuhlobene ngokuqondile nezici eziguquguqukayo zengxenye ngayinye yethuluzi lomshini.Amanani wepharamitha yesinxephezelo se-backlash kuphela angalungiswa ngokuya ngesimo sangempela.

Umsebenzisi akakwazi ukushintsha izesekeli zethuluzi lomshini ngokuthanda kwakhe, njengokusebenzisa i-hydraulic chuck ngale kwencazelo.Umkhiqizi ucabangela ngokugcwele ukufaniswa kwemingcele ehlukahlukene yesixhumanisi lapho ebeka izesekeli.Ukushintshwa okungaboni kubangela ukungafani kwemingcele kuzixhumanisi ezihlukahlukene, futhi kubangela izingozi ezingalindelekile.Ukucindezela kwe-hydraulic chuck, ukuphumula kwethuluzi le-hydraulic, i-hydraulic tailstock kanye ne-hydraulic cylinder kufanele kube ngaphakathi kwebanga lokucindezeleka elivumelekile, futhi akuvunyelwe ukwanda ngokuzenzakalelayo.

Isikhathi sokuthumela: Sep-09-2022