Izici zamathuluzi omshini we-CNC ekucutshungulweni

1. Ukunemba okuphezulu

(1) Isakhiwo sethuluzi lomshini samathuluzi omshini we-CNC sinokuqinile okuphezulu nokuzinza kokushisa, futhi izinyathelo zokunciphisa amaphutha zithathiwe.Ngephutha, ingabuye inxeshezelwe ngedivayisi yokulawula izinombolo, ngakho-ke ithuluzi lomshini wokulawula izinombolo linokunemba okuphezulu komshini.

(2) Uhlelo lokudlulisela lwethuluzi lomshini we-CNC lusebenzisa isikulufu sebhola ngaphandle kwemvume, isitimela esigawulayo, umshini wegiya one-zero clearance, njll., okuthuthukisa kakhulu ukuqina kokudlulisela, ukunemba kokudlulisela kanye nokuphindaphinda kwethuluzi lomshini.Ithuluzi lomshini we-CNC elithuthukisiwe lamukela ubuchwepheshe bemoto obuqondile, ukuze iphutha lokudlulisa ngomshini lethuluzi lomshini libe nguziro.

(3) Umsebenzi wokunxeshezelwa kwephutha wesistimu yokulawula izinombolo uqeda iphutha lesistimu.

(4) Ithuluzi lomshini we-CNC liwukucubungula okuzenzakalelayo, lisusa iphutha lomuntu, lithuthukisa ukuhambisana kosayizi wokucubungula weqoqo elifanayo lezingxenye, futhi ikhwalithi yokucubungula izinzile.Ukufakwa okukodwa kungenza ukucubungula okuqhubekayo kwezinqubo eziningi, kunciphisa amaphutha okufaka.

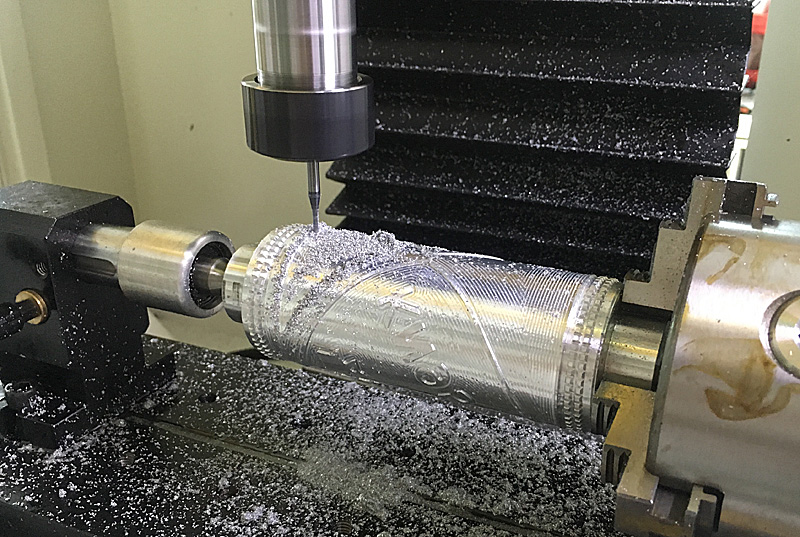

2. Ingakwazi ukucubungula izingxenye ezinobumo obuyinkimbinkimbi

Isebenzisa ithuluzi lomshini we-CNC elinezimbazo ezingaphezu kwezimbili ezixhunywe ndawonye, ingacubungula umzimba ojikelezayo, ikhamera, kanye nezindawo ezihlukahlukene eziyinkimbinkimbi zesikhala esigobile lapho ibha yebhasi yayo iyijika, futhi ingaqedela ukucubungula okunzima kumathuluzi omshini ojwayelekile.Isibonelo, uphephela wasolwandle uyingxenye eyinkimbinkimbi enomzimba ogobile wesikhala, ongacutshungulwa kuphela ngesisiki sokugaya kanye nethuluzi lomshini we-CNC oxhumene nama-eksisi amahlanu ovundlile.

3. Ukukhiqiza okuphezulu

(1) Yonga isikhathi esisizayo

Amathuluzi omshini we-CNC afakwe ngezindlela ezizenzakalelayo zokushintsha ithuluzi njengezindawo zokuphumula zethuluzi lenkomba namamagazini amathuluzi.I-manipulator ingalayisha futhi ilayishe ngokuzenzakalelayo amathuluzi nezingcezu zokusebenza, okusindisa kakhulu isikhathi sokusiza.Akukho ukuhlolwa okudingekayo ohlelweni lokukhiqiza, konga isikhathi sokuhlola.Lapho ingxenye yomshini ishintshiwe, ngaphezu kokuhlanganisa kabusha i-workpiece kanye nokushintsha ithuluzi, uhlelo kuphela oludinga ukushintshwa, olusindisa isikhathi sokulungiselela nokulungiswa.Uma kuqhathaniswa namathuluzi omshini ajwayelekile, ukukhiqiza kwamathuluzi omshini we-CNC kunganyuswa izikhathi ezi-2 kuye kwezi-3, futhi ukukhiqizwa kwezikhungo zomshini kungandiswa izikhathi eziyishumi kuye kweziningi.

(2) Khulisa izinga lokuphakelayo

Amathuluzi omshini we-CNC angonga ngempumelelo isikhathi sokuqondisa, ukunyakaza okusheshayo kufinyeza isikhathi sohambo lokungenzi lutho, futhi ububanzi bokuphakelayo bukhulu.Ingakwazi ukukhetha ngokuphumelelayo inani elifanelekile lokusika.

(3) Ukusika ngesivinini esikhulu

Ngesikhathi somshini we-CNC, amathuluzi anobubanzi obuncane, ukujula okuncane kokusika, ububanzi obuncane bokusika, kanye nokudlula okuningi okusheshayo kusetshenziselwa ukuthuthukisa ukusebenza kahle kokusika.

Amandla okusika omshini wejubane eliphezulu ancipha kakhulu, futhi itorque yokuphotha edingekayo iyancipha ngokufanayo.

I-deformation ye-workpiece nayo incane.Ukusika ngesivinini esiphezulu akugcini nje ngokuthuthukisa ukukhiqiza, kodwa futhi kusiza ukuthuthukisa ukunemba kwemishini kanye nokunciphisa ukukhahlamezeka kwendawo.

Ukuvumelana nezimo kanye nezici zezomnotho zamathuluzi omshini we-CNC

1. Ukuzivumelanisa nezimo okuqinile

Amathuluzi omshini we-CNC angakwazi ukuzivumelanisa nokucutshungulwa kwama-workpieces ezinhlobonhlobo ezahlukene, imininingwane kanye nosayizi.Lapho ushintsha izingxenye ezizokwenziwa ngomshini, kudingekile kuphela ukubopha i-workpiece nge-fixture yendawo yonke, ukushintsha ithuluzi, futhi ushintshe uhlelo lomshini, futhi umshini ungenziwa ngokushesha.Isistimu yokulawula izinombolo zekhompyutha ingasebenzisa isofthiwe yokulawula isistimu ukuze ikhulise noma iguqule kalula imisebenzi yohlelo lokulawula izinombolo, futhi ingahlangabezana nezidingo zokuthuthukiswa kokukhiqiza.

2. Isiza ukuthuthukiswa kwezinhlelo zokukhiqiza ezithuthuke kakhulu

Amathuluzi omshini we-CNC ayisisetshenziswa esiyisisekelo sokuzenzakalela ngomshini.Amaseli omshini ovumelana nezimo (FMC), amasistimu okukhiqiza aguquguqukayo (FMS) kanye nezinhlelo zokukhiqiza ezididiyelwe zekhompyutha (CIMS) zonke zisekelwe kumathuluzi omshini we-CNC.Ithuluzi lomshini we-CNC elilodwa noma ngaphezulu, kanye nezinye izinto ezisizayo (ezifana nezinqola zokuthutha, amarobhothi, amabhentshi okusebenzela ashintshayo, izindawo zokugcina izimpahla ezinezinhlangothi ezintathu, njll.) zakha isistimu yokukhiqiza ezenzakalelayo.Uhlelo lokulawula izinombolo lune-interface yokuxhumana, okulula ukuxhumana phakathi kwamakhompyutha futhi uqaphele ukuphathwa kwekhompyutha nokulawula inqubo yokukhiqiza.

3. Umnotho wamathuluzi omshini we-CNC

Izindleko zamathuluzi omshini we-CNC ziphakeme kunalezo zamathuluzi omshini ojwayelekile, futhi izindleko zokucubungula ziphakeme kakhulu.Ngakho-ke, akuzona zonke izingxenye ezilungele ukucutshungulwa kumathuluzi omshini we-CNC, futhi inohlu oluthile lokucubungula izinhlelo zokusebenza.Ukuthi ilungele yini ukucubungula ithuluzi lomshini we-CNC kufanele kunqunywe ngokuya ngohlobo lokukhiqiza, usayizi wesakhiwo nokuba yinkimbinkimbi komkhiqizo.

Ithuluzi lomshini wenhloso evamile lifanele ukukhiqizwa kwesiqephu esisodwa kanye nenqwaba encane, futhi isakhiwo sokucubungula asiyinkimbinkimbi kakhulu.

Amathuluzi omshini akhethekile afanele ukucutshungulwa kwenani elikhulu lama-workpieces.

Amathuluzi omshini we-CNC afanele ukucutshungulwa kweqoqo lezinto zokusebenza eziyinkimbinkimbi.

Izici zamathuluzi omshini we-CNC ekuphatheni nasekusetshenzisweni

Amathuluzi omshini we-CNC ayabiza ukuwenza, futhi ayisisetshenziswa esibalulekile semikhiqizo ebalulekile nezinqubo ezibalulekile ebhizinisini.Uma umshini wehlulekile, umthelela nokulahlekelwa kuzoba kukhulu.Njengemishini ye-mechatronics, amathuluzi omshini we-CNC anezici zawo.

Izinga lobuchwepheshe lokuphatha, ukusebenza, ukulungiswa kanye nabasebenzi bezinhlelo liphezulu uma kuqhathaniswa.Umthelela wokusetshenziswa wamathuluzi omshini we-CNC uncike kakhulu ezingeni lobuchwepheshe lomsebenzisi, ukwakhiwa kobuchwepheshe bemishini be-CNC kanye nokunemba kwezinhlelo ze-CNC.Ngakho-ke, ubuchwepheshe bokusetshenziswa kwamathuluzi omshini we-CNC akuyona inkinga yokusetshenziswa kwemishini evamile, kodwa iphrojekthi yohlelo lobuchwepheshe lwamathalenta, ukuphatha, nezinhlelo zemishini.Abasebenzisi bamathuluzi omshini we-CNC kumele babe nolwazi olucebile lwenqubo, futhi ngesikhathi esifanayo babe namandla okusebenza aqinile ekusetshenzisweni kobuchwepheshe be-CNC, ukuze kuqinisekiswe ukuthi amathuluzi omshini we-CNC anezinga eliphezulu lobuqotho kanye nezinga lokusebenza.

Izinhlobo zezinhlelo ze-CNC

Uhlelo lwe-NC luhlukaniswe izigaba ezimbili: ukuhlela okwenziwa ngesandla kanye nokuhlela okuzenzakalelayo.

1. Ukuhlelwa kwezinhlelo

(1) Ukunquma inqubo yezobuchwepheshe Ngokusho kwengxenye yomdwebo, ukuhlaziywa kwenqubo kuyenziwa, futhi imingcele yezobuchwepheshe efana nomzila wezobuchwepheshe, ukulandelana kwesinyathelo sokusebenza, inani lokusika nokunye kokucutshungulwa kwengxenye kunqunywa.Nquma amathuluzi kanye nenani lamathuluzi ozowasebenzisa.

( 2 ) Bala ithrekhi yomshini nosayizi

(3) Bhala uhlu lohlelo bese uluqinisekisa

(4) Faka okuqukethwe kohlu lohlelo Okuqukethwe kohlu lohlelo lokulawula izinombolo kufakwa edivayisini yokulawula izinombolo ngomshini wokufaka.

(5) Ukuqinisekiswa nokusikwa kwesilingo sohlelo lwe-NC Qala idivayisi ye-NC, yenza ithuluzi lomshini we-NC liphele, futhi uhlole ukufaneleka komzila wohlelo.Sebenzisa izinkuni noma imikhiqizo yepulasitiki esikhundleni se-workpiece yokusika isivivinyo ukuze uhlole ukunemba kwenani lokusika.

(6) Ukusika kwesivivinyo kwesiqephu sokuqala

2. Ukuhlela okuzenzakalelayo

Inqubo yokuhlanganisa izinhlelo zemishini ye-CNC ngosizo lwekhompyutha ibizwa ngokuthi i-automatic programming.

Ezingxenyeni ezinejometri eyinkimbinkimbi, ukuhlela okwenziwa ngesandla kudinga abasebenzi abaningi futhi kunephutha.

Ukuhlela nokubalwa kwezingxenye ezingaphezulu kwesikhala kunzima kakhulu, futhi umsebenzi wezandla awunalo ikhono.Ohlelweni oluzenzakalelayo, ukubalwa kwedatha yezixhumanisi ze-node, ukukhiqizwa kwezindlela zamathuluzi, ukuhlelwa nokukhishwa kwezinhlelo konke kwenziwa ngokuzenzakalelayo yikhompyutha.

Isikhathi sokuthumela: May-23-2022